Igwe frying Vf-Intelligent Vacuum Frying Machine

Uru

- Na-egbochi mmebi nke abụba na mmanụ a na-eri eri, meziwanye ojiji nke mmanụ ugboro ugboro, Belata ego, ọdịnaya mmanụ nke nri eghe n'ozuzu dị elu dị ka 40% -50%, mmanụ mmanụ nke ighe frying bụ 5%-10%.

- Mmiri mmiri na-ekpo ọkụ mmanụ dị ala na-ekpo ọkụ nwere ike ime ka nri e ghere eghe ghara ịdị mfe ịla n'iyi na agba aja aja nwere ike ịnọgide na-agba agba nke ngwa ahụ n'onwe ya.

- Teknụzụ frying na-ekpo ọkụ nwere ike ichekwa isi ísì nke akụrụngwa n'onwe ya.

- Site na frying dị ala, a na-echebe uto mbụ nke ngwaahịa ahụ.

Usoro eruba

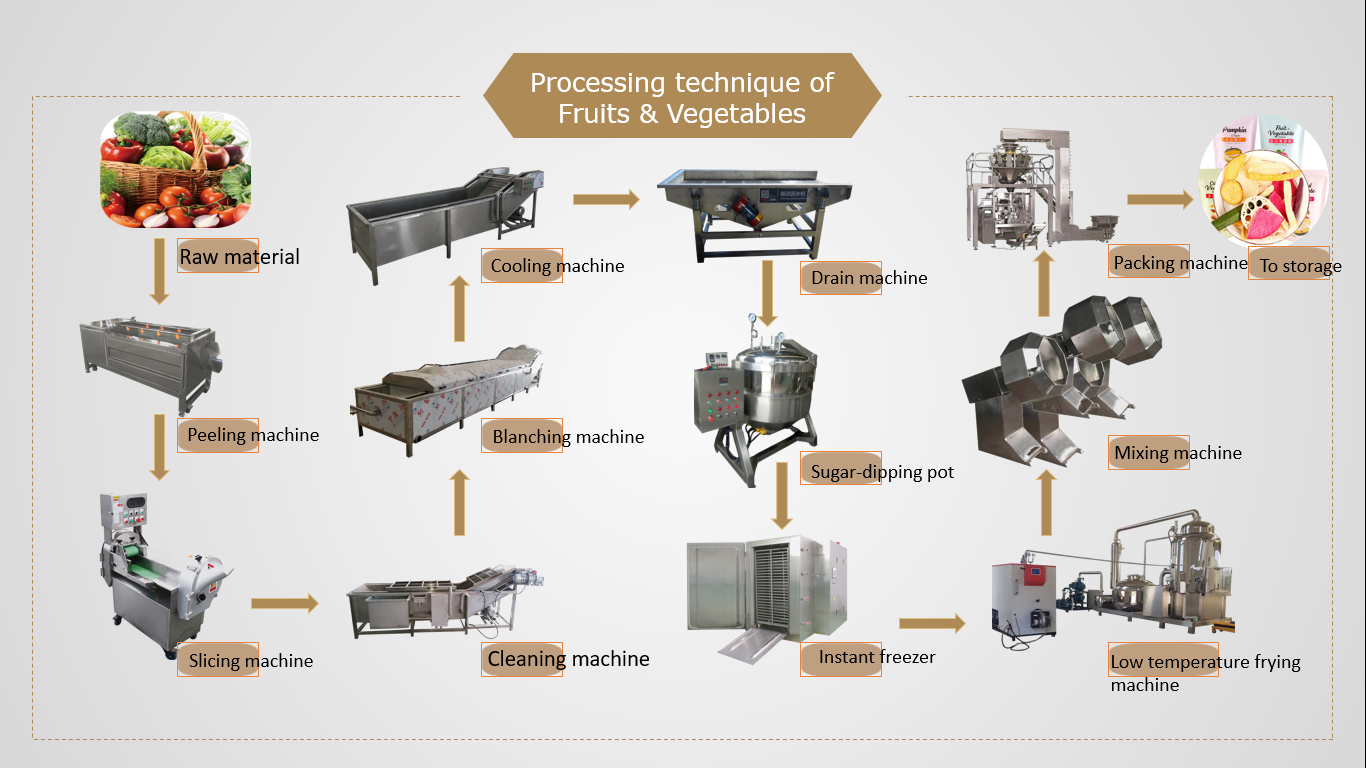

Ngwa ngwa → nyocha → ihicha → slicing (ịcha) → blanching (nchekwa agba) → igbapu → friza → thawing → dipping (vacuum impregnation) → ihicha → igbapu → vacuum frying → agụụ deoiling → seasoning → ngwaahịa nkwakọ → nchekwa.

Usoro nka

| Parameter/Nlereanya | VF-1200 | |

| Ike nhazi (ihe akụrụngwa n'arọ n'arọ / oge) | 2400-300kg | |

| Oge nhazi (nkeji / oge) | Ihe dịka 50-180min | |

| Oke ogo agụụ (MPA) | -0.093≈-0.098mpa | |

| Okpomọkụ mmanụ (℃) | 80-120 | |

| Isi mmalite kpo oku | Isi mmalite isi | uzuoku |

| Oriri uzuoku (kg/h) | 300 | |

| Nrụgide Steam(MPA) | 0.4-1.5 | |

| Ụzọ ọkụ isi | Mpụga mgbasa nke mmanụ mgbapụta | |

| Ọsọ iweda n/min | 0 ~ 400 | |

| Oke mmiri jụrụ oyi (T/H) | 15 | |

| Ịnye ọkụ | Elecricity Ststem | 380V |

| Mgbakọta ike(kw) | 37kw | |

| Otu akụrụngwa na-ekpuchi mpaghara (mm) | 5800*2200*3800mm | |

| Ọnụ nkata fryer (pcs) | 1 ibe | |

| nkata fryer sise(mm) | Dayameta 1200*600mm | |

| Ebe nchekwa tank mmanụ (L) maka imegharị ihe | 2500L | |

Nchịkọta nke agụụ frying

Nri, ịdị mma, nchekwa na akwụkwọ ndụ akwụkwọ ndụ bụ usoro mmepe nke mmepụta nri.Iberibe mkpụrụ osisi na akwụkwọ nri nwere ekpomeekpo pụrụ iche na ọdịdị dị ọcha na-ewu ewu na mba ndị mepere emepe na mpaghara dịka Europe, America, Australia, Japan, Hong Kong na Taiwan.Na China, site na mmụba nke ụkpụrụ ndụ mmadụ na-aga n'ihu, ndị mmadụ na-achọwanye nri ụtọ eke.N'obodo mepere emepe dị ka Beijing, Shanghai, Yunnan, Shaanxi, Mongolia Inner, Tibet, Tianjin na ndị ọzọ, ndị ahịa ejirila obi ụtọ na-achụso ha.Enweghị ngwa ngwa ngwa ngwa maka ngwaahịa.

(1) Ụkpụrụ nke agụụ na-ekpo ọkụ dị ala ighe mmiri na ihicha:

A na-eji mkpụrụ osisi na akwụkwọ nri mee ibe mkpụrụ osisi na akwụkwọ nri ọhụrụ dị ka isi akụrụngwa, mmanụ ihe oriri dị ka ihe na-ekpo ọkụ, na ighe obere okpomọkụ frying (VF vacuum) Fryer na teknụzụ ndị ọzọ dị elu nwere ike kpọchaa mkpụrụ osisi na akwụkwọ nri ngwa ngwa. obere mmiri dị n'ime obere oge, nke nwere mmanụ dị ala, nke na-adịghị mma ma ọ bụghị abụba, na-echekwa ọdịdị mbụ, agba, ísì ụtọ na uto nke mkpụrụ osisi na akwụkwọ nri, na ọgaranya vitamin, mineral, fibers na ndị ọzọ na-edozi ahụ, na-adị ala. shuga, obere nnu, obere abụba, obere okpomọkụ na njirimara ndị ọzọ.

Para fabricar chips de frutas y verduras, frutas y verduras frescas son materiales principales, aceite vegetal es el medio de calentamiento, y la freidora al vacío de baja-temperatura (Freidora al vacío VF) puede deshidratarás con contenuti con y seid. de agua, en un período de tiempo muy corto, y con muy bajo contenido de aceite, los chips son crujientes pero no grasientos, se mantiene su forma, color, sabor de las frutas y verduras, además, se contiene abundante de vitamin, minerales. , fibres y otras nutriciones, y poco azúcar, sal, grasa, caloría y otras características.

(2) Vacuum frying obere okpomọkụ ọdabara na oke nri:

1 Mkpụrụ osisi: apụl, unere, macaques, painiapulu, jujube oyi, strawberries, jackfruit, wdg.

2 Akwụkwọ nri: dị ka karọt, radish, nduku dị ụtọ, ugu, galik, yabasị, ero oriri, gourd wax, okra, wdg.

3Anụ: dị ka anụ ehi, fillet azụ, oporo, octopus, wdg.

(3) Usoro frying Vacuum:

Akụrụngwa → nyocha → nhicha → slicing (ịcha) → cyanding (nchekwa agba) → drainage → friza → vacuum frying → vacuum de-oiling → seasoning → nkwakọ ngwaahịa → nkwakọba ihe.

Nkọwa zuru ezu nke akụrụngwa

Ụlọ ọrụ anyị na-ewebata nhazi zuru oke nke mba ọzọ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-ekpo ọkụ na-emepụta ihe na-ekpo ọkụ na-esi na mmalite dị elu.Nkà na ụzụ na-ebute ụzọ na otu ụlọ ọrụ na China.Ngwá ọrụ frying na-ekpo ọkụ nke ụlọ ọrụ anyị na-emepụta bụ nke ụdị nkwụsịtụ.

(2) Nhazi akụrụngwa na ndepụta nhazi

Usoro nhazi nke igwe frying oghere bụ nke a

Kettle frying Vacuum, Sistemụ na-ekpo ọkụ na-ekesa mmanụ, Sistemụ agụụ, Sistemụ mkpofu mmiri, Sistemụ iwepụ mmanụ akpaka, sistemu njikwa ọkụ.

(1) Usoro ihe eji eme ihe na-agụnye kettle oghere, ihe mkpuchi mmiri vapor trap condenser, mgbanaka mgbanaka mmiri, mmiri na-eme ka mmiri dị jụụ na valves na pipeline yiri ya.A na-eji ya na-ekpochapụ usoro ahụ ma mee ka ọ dị elu n'oge frying.

(2) Igwe ọkụ ọkụ ọkụ mmanụ mmanụ mejupụtara valvụ nkwụsị, valvụ solenoid valvụ, valvụ nchekwa na valvụ ndị metụtara ya, pipeline na ngwaọrụ nlekota oru.Maka kpo oku mmanụ nri.

(3) Usoro njikwa ọkụ eletrik mejupụtara PLC nke ama ama nke mba ụwa, ihuenyo mmetụ na ngwa eletriki dị ala, nke a na-eji maka nchekwa sistemu na njikwa akpaka.

(4) A na-eji usoro de-oiling maka vacuum centrifugal de-oiling na njedebe nke frying iji belata ọdịnaya mmanụ nke nri e ghere eghe.